- English - Deutch - Français - Español - Italiano - 日本語 -

Proceed according to the user guide in order to understand your LRP VECTOR X12 Brushless Modified motor better. Please take your time as you will have much more joy with your product if you know it exactly. This user manual shall be kept in a safe place. If another customer is using this product, this manual has to be handed out together with it. At present, it is the high power touring cars that are making the biggest demands on power and reliability of brushless speed controls. But now LRP electronic is proud to release the all new SPHERE COMPETITION TC Spec Brushless + Brushed speed control — the next milestone for the future of RC competition racing: BRUSHLESS! The LRP SPHERE digital speed control will give all brushless drivers the same perfect drive feeling they know from a high-end brushed speed control as the LRP Quantum Competition 2! 4 Modes Drivers around the world love the possibility to customise the LRP QC-2 with its easy and comprehensible mode system with 2 buttons for adjustment and 2. Funktionstest LRP Sphere Competition TC Spec mit Vector X 11 6.5 Turn MrAbakus66. Unsubscribe from MrAbakus66? Cancel Unsubscribe. Subscribe Subscribed Unsubscribe 3. The principal components of the Qabalistic Cross and the Lesser Ritual of the Pentagram are drawn from the works of Eliphas Levi. The text originated as a Jewish prayer, as documented by R. Samson Raphael Hirsch in 'The Hirsch Siddur' Feldheim Publishing, 1969, which reads as follows: 'In the Name of God, the God of Yisrale: may Michael be at my right hand, Gabriel at my left, Uriel before.

If you want to add information (setup, tips ...) to this page, please send email to: arn0(at)petitrc.com (replace (at) by @)

|

Made by Arn0 - 2017-02-07

Team Associated Factory Team TC4 Setup Tips by Lufaso

There are many variables involved insetting up a Team Associated Factory TC4 radio controlled racing car. It is not possible to give a setup that will work with all tracks anddriving styles. I give a starting point for the various parametersinvolved in setting up the Team Associated Factory Team TC4 based on the setups I have tested. Thoroughly read the manual given with the Factory Team TC4. CompetitionX also has information, updates, and tips. The Team Associated RC Handbook is useful. Read RC Car handling to begin to understand what each change will make. HPI also has a tuning guide worth reading.Construction and Assembly

Chassis/Components:

Startwith the Team Associated Factory Team TC4 Kit (#30102). Duringassembly, check each part and remove the flashing if necessary. Thechassis preparation starts with sanding the outside edge of the chassisand also the battery slots. If you do not sand the battery slots, it isvery likely that the battery tape will be cut. Team CRC has a nicedescription on how to prepare a carbon fiber chassis.

Front/Rear Suspension:

The front and suspension should be free and smooth. Without the shockinstalled, the arms sould raise and fall freely under their own weight. Check the inside and outside hinge pins to ensure they are straight.

Bumper:

The dense front bumper can be lightened by taking some material from the underside with a Dremel tool.

CVD's:

I break in the CVD's, bearings, and differentials by using an old motorhooked up to a battery pack or motor run-in feature on the LRP charger. This will free up the drivetrain before you get to the track.

Shock Assembly:

Lrp Sphere Manual

Follow directions included in kit. Apply Green Slime to build a smoothset of shocks, and lightly coat the shock shaft/o-ring seals. Fill theshock bodies with desired weight oil and bleed the shocks. The mostimportant tip is to ensure the rebound is equal on both shocks. Itypically assemble shocks with very little rebound, but the mostimportant part is that each is equal. Wrap a piece of paper around theshock shaft, the use little pressure to hold the shock shaft,minimizing the chance to scratch with pliers. Measure the distance fromthe shock body to the ball cup and adjust until both are even. Readmore about shock oil weights at Team TWF8. ws. By following the instructions and a little practice, the stock shockswork just fine. I have never had one leak that was properly assembled.Weight :

The car is under the ROAR minimum weight. Add motor cooling fans (AE #31036) and heatsinks (narrow #3927, wide #3928, or wrap around #31049, or use extra lead weights (AE #1595) to balance the car.

The car is under the ROAR minimum weight. Add motor cooling fans (AE #31036) and heatsinks (narrow #3927, wide #3928, or wrap around #31049, or use extra lead weights (AE #1595) to balance the car. Handling

Setting the Tweak:

I don't claim to know the best way to set the tweak on the car. I'lldescribe how I set the tweak using a Niftech tweak board, but similartweak boards will work as well. Feel free to send me a suggestion on abetter method. First make sure the tires (if using foam) sizes areclose to even. Check to make sure the shock springs are the same length(these do vary!). Make sure the shock body to beginning of ball cup isthe same length. Set the ride height to 5-5. 5 mm at each corner. Makesure the camber is set properly (~-1 to -2) for the tires to wearevenly, no coning in either side of the tire. Remove the wheels and setthe droop (equal right to left) to whatever is appropriate for the rollcenter setup, tire size, etc. . Reinstall the wheels and have allequipment installed like the car will be raced. Ensure tweak board islevel in all directions. Place the rear tires on the solid portion ofthe tweak board, with the front chassis flat on the part of the tweakboard that rotates, or on top of a level spacer. Adjust the shocksetting to obtain an even tweak for the rear. Now place the front tireson the solid portion of the tweak board, and rear part of the chassison the part that rotates, then adjust the tweak for the front. Afterthe front and rear are adjusted separately, place all four wheels onthe tweakboard. The tweak should be very near level. Perform any slightadjustment if it is necessary, but don't make all the adjustment in asingle shock, spread it out evenly over the 4 shocks. Be sure to pressevenly on the center of the suspension after each step and adjustmentto make sure there is no bias and to settle the suspension. I recordthe distance between the collar and shock hex.

In my opinion, it doesn't matter at allwhat the tweak board shows, it's how it handles on the track. Afterfollowing the above steps drive the car on the track in practice. Ifthe car doesn't handle evenly on the track, then adjust all four shockcollars until it steers evenly left and right. After getting the car tohandle evenly, put the car back on the tweak station with all 4 wheels. I measure/estimate how much the bubble is off center and write it down. I do the same thing for the front and rear, with the chassis resting onthe tweak plate, recording the values for the tweak offset on the tweakboard. Remeasure the shock collar to hex distances. Now I have asetting that will allow me to purposely adjust the car so that althoughit is not tweaked according to the tweak board, it handles evenly onthe track.

I have not tried adjusting the tweak by the X-acto blade method. Read an alternative method 1 and 2 for using the MIP tweak board. HPI also describes how to set the tweak.

Tires:

are one of the most important aspects of the car. Jaco Double Pink forthe rear, and Orange/Double Pink on the front work well for foam tireson carpet. A tire durometer can match the hard/softness. There willalways be an approximately gaussian distribution of tire compounds, asthe range of compound density in foam rubber production will always bepresent. Matching the tires can be useful, often a car that is 'tweaked' may just have a mismatched set of tires. If you get multiple sets offront tires at the same time, match the width of the orange foam. Amore narrow orange strip will give more steering than a wide orangestrip. Apply CA glue on the sidewalls will prevent the tire separatingfrom the wheel when the tire becomes very small, or when spearationoccurs due to the high cornering speeds. CA on the sidewall alsoslightly stiffens the sidewall for high traction surfaces. Rubber tiresare more straightforward, but I only have experience with premountCS-27 since that is what many races use.

Foam Tire Size:

The 'best' tire size is the smallest in which enough traction isavailable for the entire 5 minute run, and maintains enough ride heightto meet ROAR rules 0. 125' and not drag and rub on track. Typical tiresizes for carpet range from 2. 2' to 2. 3' on the front for a smoothtrack. Tire weight is a major factor in determining the size to use. Onvery low traction asphalt tracks that are dusty, I prefer to use largertires, sometimes as large as 2. 5' to obtain more side bite due tosidewall flex/roll.

Ride Height:

The car is riding too low when the front of the chassis/body mountscrews are blackened after a run. I typically run the ride height atabout 0. 150' to 0. 175' (approx 5 mm) for very smooth tracks and a stiffsuspension setup. For a softer spring setup or rougher track, a higherride height of 5. 0 mm or above should be used.

Turning circle:

Adjustment of the turning circle is critical in obtaining consistentand equal left and right steering. The dual rate should be adjusted to100%, then the individual right and left steering endpoints adjusted tothe maxmimum physical value allowed (steering block touching carrier). Take the car to the track and place it next to a board. Turn the wheelright to the maxmimum and drive the car in a half circle. Mark the spotof the outside tires. Pick up the car and place it back against theboard. Turn it to the left and drive a half circle. Decrease thesteering on the side that has a smaller turning circle and repeat untilboth left and right turning circles match. The dual rate adjustment maythen be turned down to about 80-95%. I leave extra adjustment in casethe car has a slight understeer, which I increase the steering duringthe race. The minimum possible amount of steering throw should be usedon the track in order to have the greatest sensitivity and control inthe steering. Excessive steering throw and a understeering car is veryinefficient because the front tires will be scrubbing speed, althoughit is easier to drive. This has to be balanced with the ability to turnthe car around in case of a crash.

Tire Traction:

The standard traction compound for use on ozite based carpet is ParagonGround Effects. There are many important factors in it's use - whichcan be quite an effective tuning agent. The length of time the tractionstays on is important. For tracks with low traction, it should beallowed to soak in for a longer period of time. On high traction track,a few minutes may be all the is necessary. The amount applied is alsoconsidered - in most cases I see racers putting on much more thannecessary for the track conditions. This can actually slow the car downas the softer tire tend to scrub more speed - slowing the car down andreducing run time and efficiency. It is also beneficial to change tireseach run to prevent traction build up. I typically run only one set oftires a few times a day (using those same sets again the next race dayand I sometimes alternate between 2 sets.

Indoor tracks which donot allow Paragon, but do allow odorless traction compounds, I havetried Paragon Traction Action, FXII, Corally 'Jack the Gripper' and TQOrange based traction compounds. The compound should be allowed to soakinto the tires for longer than paragon (approx 35. minutes ifpossible). Rubber tires are an entirely different matter that dependson the tire, traction applied to the track, and track temperature. TryParagon FXII and see what the fast guys are using.

Front and Rear Springs:

Lrp Sphere Tc Spec Manual

Onhigh traction carpet where the steering is high, I use the yellow,purple, or copper on the front. The rear spring is most often copper,or the same or softer than the front springs. It depends on the amountof steering needed, bumps on the track, and responsiveness desired. RCracingingreece.com has a comparison of different manufacturer springs.Front and Rear Oil:

Onhigh traction carpet, I range I use is Associated 60-40 wt with #2pistons in the front, with Associated 50-35 wt with #2 pistons in therear. On tighter tracks, decrease the weight in both shockssimultaneously if the cars handling is close to desired. Decrease theoil viscosity if the tire size is large or the car is chattering in thecorners. See the setup sheets above for what I use for differenttracks.

Arm Mount Shimming/Roll Center:

Seethe next to last page of the TC4 instruction manual for how the armmount shimming affects the kick-up, anti-dive, anti-squat, andpro-squat. Anti-dive reduces weight transfer to the front ondeceleration entering the corner. Kickup makes the front suspensionstiffer. Anti-squat makes the rear suspension stiffer and gives the carmore entry steering and reduces rearward weight transfer on power. Pro-squat increases rearward weight transfer on power. Generally, oncarpet a lower roll center is used. For rubber tires, try the standardsettings. There are some software programs, such as the Roll Center Calculator that one could try to calculate the roll centers. Experiment to see what works best for you.

Chassis Rake:

The chassis should be very nearly level - to within 0. 5mm and this isanother way to tune the handling. By having the front end lower thanthe rear, more steering can be obtained and conversely having the rearend lower the the front will create less steering. Note that is validonly to a small tuning amount and can not be taken to extremes (>1. 0mm).

Caster:

More negative caster gives more high speed steering, and less low speedsteering. Typically use 2-4 degrees total, with 4 being standard.

Front and Rear Camber:

I use a Team Associated or RPM camber/caster gauge to measure and tuneeach side to measure the same. I use about -1. 0 to -1. 5 degrees ofcamber, which allows the tire to wear evenly. I adjust the camber untilthe tire wears evenly and do not use this as a tuning parameter oncarpet. On rubber tires, slightly less camber (-1 degree).

Anti-Dive/Kick-up:

More anti-dive reduces weight transfer to the front on decelerationentering corners, and reduces caster. Kick-up makes front suspensionstiffer and adds caster.

Anti-Squat/Pro-Squat:

More anti-squat makes the rear suspension stiffer, more entry steering,and reduce rearward weight transfer on power. Pro-squat will increaserear weight transfer on power.

Front and Rear Shock Position:

A more vertical position is stiffer, more responsive, but lesstraction. The setting correlates with the spring and oil choice. Experiment to see what works best for you. The more vertical the shock,the stiffer the spring force, and conversely the more angled the shockthe suspension is softer. As the shock changes angle upon travel, thereis some progressive response.

Wheelbase:

Moving the front or rear wheels towards the center of the car will result in more traction at that end of the car.

Sway Bar(s):

Swaybars are an effective way to fine tune the car. The baseline setup isto use the stock front sway bar. Set up the car using all otheravailable parameters before fine tuning with a rear sway bar. I use thestock TA or thin 0. 055' BRP swaybar on the rear to control body rolland amount of steering. The multiple swaybar kit, with 3 thickness barsis available AE. Setting the sway bar.

- 1 - Make sure you have the droop set, and it's equal on both sides(I. e. if you're trying to run less droop on one corner- notrecommended- then do it after you set your rollbar)

2- install the bar and make sure it moves freely on the tranny mounts.

3- install the pivot balls and caps, make sure not to over-tighten thecaps and the ball moves freely.

4-hook everything up

5- hold on side down against the stop and press up on the opposite armout at the hub. If there is a 'dead spot' with no resistance, lengthenthe link on that side, if there is a lot of resistance, shorten thelink. Check the opposite side as well and repeat until there is equalresistance when pushing up

6- double check your settings by flipping the car upside-down. hold oneside against the stops and inspect the gap between the droop screw andthe opposite stop. Check and see if both sides are the same. If one gapis larger, shorten that link (remember that also grows the gap on theopposite arm so use small increments.

In the end you should pass both tests and each side should move at anequal time when lifting the opposite arm. Be careful not to shorten thelinks too much and pinch the upper ball inside the eyelet. If you can'tshorten the left side any more, then it's time to lengthen the right. Hopefully none of your swaybars are so tweaked that you run out ofadjustment. Then, just re-bend the bar or preferably get a new one.

Gearing:

Gearing depends on the track size, motor anddriving style. A good starting point can be found in the TC4 manual,which is about 10 teeth over the number of turns in the modified wind. It depends on the track size. For large tracks, try up to 15 teeth(e. g. 48 pitch, 25/72 for a 10 turn) over the wind. I prefer to use therollout sheets to determine the rollout number for gearing. This ismuch more comparable between cars and tire sizes. Check the setupsheets for more info.

Maintenance

Differential:

Theplastic differentials require checking more often than the steelversion. Check the tightness after every run. The differential shouldnot slip under normal acceleration (off of a corner). The plasticdifferential my heat up and grab when using a low turn modified motor. The car will develop oversteer during the race. Check the diffimmediately after the race, it should still be smooth. Disassemble thedifferential and check for parts that may be rubbing together - youwill notice a ring on either diff half. The plastic diff weight is 0. 42oz, while the steel diff is 1. 00 oz. One compromise is plastic in frontand an Aluminum or steel in the rear. One takes a chance of breakingthe diff outdrive. The most reliable differential is steel in front andrear, which is what should be used (or aluminum) in modified. Replacethe differential thrust spring, with initial length ~ 0. 285' andreplace when noticeably shorter, i. e. < 0. 260'. Use the standard kitgreases.

Equipment

Body:

Parma Alfa (190 mm Part Number 10089)for foam tires can be lowered thefront completely until the shock tower was touching the body and therear I have mounted so the body is as low as possible, while meetingthe minimum body height of the particular race (sometimes 117 mm (4. 625inches) and sometimes lower. The rear bumper cutout may only be 55 mm(2. 165') with 20 mm (0. 787') blocks under the chassis. It may benecessary to drill new holes for the rear body mounts. Protoform makesexcellent bodies, incliding the Stratus 2. 0,3. 0, Mazda 6, Alfa andothers that all handle great.

Paint:

Parma/PSEFaskolor is a great nearly odorless paint for Lexan bodies. A widevariety of colors is available. Airbrushing and cleanup is simple withthe non-toxic aqueous based paint. The paintmasks make painting a nicelooking body much easier.

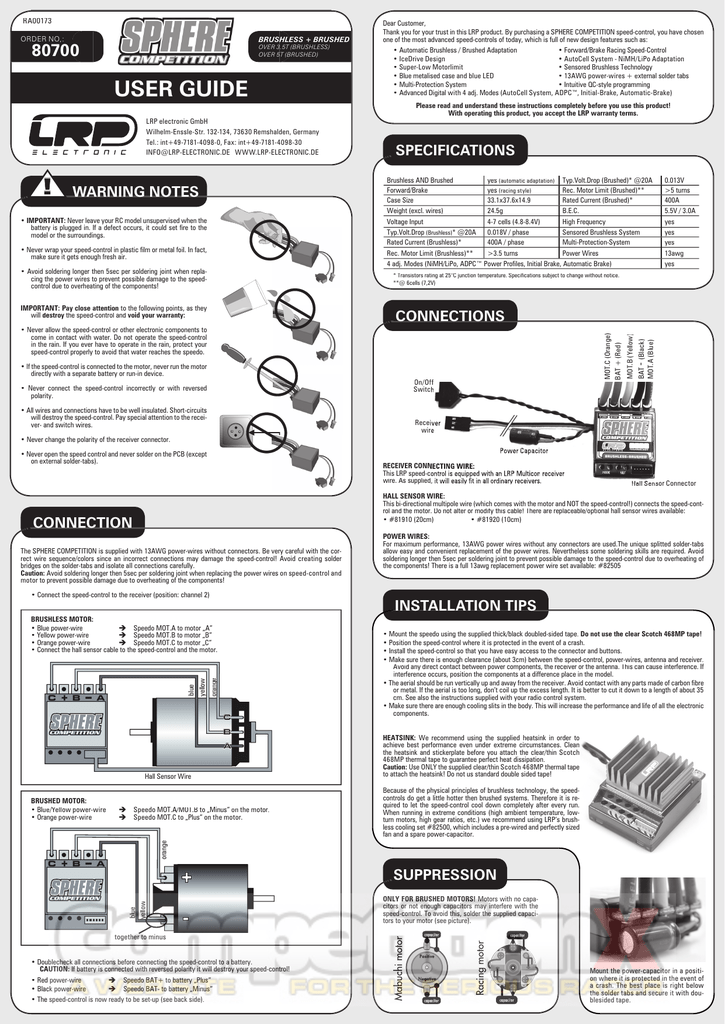

Speed Control:

LRP Quantum 2imported by Team Associated has performed flawlessly, even in hightemperature environments. The large capacitor in the 'worlds kit' helpsin reducing the large current spikes the battery pack is subjected towhile using the 7 to 10 turn modified motors. I have also experimentedwith the LRP Sphere brushless.

Servo:

Servo:1/10 touring car racing needs a fast servo, with medium torque. I currently use an KO Propo 2343, which have a good combination of torque and fast rotation speed.

Transmitter:

Iuse the KO Propo EX-10 Helios with the wheel drop down extension. Puttennis wrap around the grip to make the radio more comfortable . A fewlayers of tape attached to the brake trigger helps provide moresensitivity and quicker response for braking. The most important setupparameters are to set the throttle high point at the maximum value, 150for the KO. Another important setup is to make sure the turning radiusis set with the dual rate at 100%, then set the maximum left and rightturning circle. Adjust each so it is nearly hitting the physical limit,then adjust the side that has the smaller turning circle to match theside that has the larger turning circle. Next adjust the dual rate to90%. I use the steering curve at -20% to -50%, which makes the careasier and have finer control at high speeds and large radius corners. On some transmitters this is called the steering exponential.

Cells:

Iuse Reedy GP 3300, however if you are a beginner you do not need highvoltage cell, and can get good performance by buying lowerruntime/voltage cells. The key is to learn the mechanically/technically setup the car. When you are driving perfect lines and notcrashing for the entire race then the better cells will be a help, tryto get within 0. 3 sec per lap consistency. Get track time!

Battery Charger:

The method of charging NiMH cells is important. Read through forums andwhat the battery matchers suggest for charging the cells, but avoidoverheating and causing damage to the cells. The LRP Pulsar 2 is an excellent choice with a variable current and peak detection limit, and can run in motors.

Driving Advice

Transition from Stock to Modified:

Don't try to drive as hard into the corners as you do in stock. Straight line and corner speed is much more in mod, making any handlingimperfections in your car more noticeable. Mod requires a smooth SCthrottle curve, and areas in the infield require varying degrees ofthrottle (1/4, 1/2, and everywhere in between). Practice is the key,learn to be smooth before fast. Try high turn modifieds at club races,then go back to stock for a regional or National level race. You'll besurprised with your improvement.

Created August 29, 2005

Modified June 21, 2006